According to the New Materials Research Society, with the rapid development of the automotive industry, lightweight, comfortable, green, and environmentally friendly have become the main directions for the development of the automotive industry. Automobile lightweight technology can reduce body weight and fuel consumption, and is one of the important measures to achieve energy conservation and emission reduction. At present, plastic materials are increasingly used in automotive components to replace bulky and expensive metal components. 'Replacing steel with plastic' has become the best solution to meet the development requirements of the automotive industry. The degree of automotive plasticization has become an important indicator of the level of automotive design and manufacturing.

Modified polypropylene refers to the process of adding one or more other substances to a polypropylene resin to change its original properties, improve one or more aspects of its performance, and expand its applicability. Modified polypropylene materials are collectively referred to as 'modified polypropylene'.

Polypropylene (PP) modified materials have the advantages of non-toxic, acid and alkali resistance, low water absorption, easy processing, and good dimensional stability.

The Automotive Advantages of Polypropylene

1. Performance advantages

Polypropylene is superior to polyethylene in strength, stiffness, hardness, and heat resistance; It can be used normally at 100 ℃, and has good dimensional stability, thermal stability, good mechanical properties, high impact resistance, strong mechanical properties, good chemical stability and is not affected by humidity. Polypropylene has a transparent and lightweight appearance, with a density of 0.89~0.91 g/cm3, making it one of the lightest varieties of plastics currently.

Therefore, using polypropylene instead of traditional metal materials can further reduce weight. In addition, due to the development of polypropylene modification technology in recent years, polypropylene occupies absolute advantage in the development of automobile industry.

2. Environmental advantages

Polypropylene is a non-toxic, odorless, and milky white transparent high crystalline polymer, which is an environmentally friendly material. Polypropylene is not only recyclable, but also contains tertiary carbon atoms in the main chain of polypropylene, which can undergo molecular chain decomposition reactions under high temperature and oxidation, giving polypropylene degradation characteristics and greatly reducing environmental problems caused by white pollution.

3. Cost advantage

There are various sources of raw materials for polypropylene production, mainly including oil, coal, methanol, propylene, etc. Coal based polypropylene is currently the fastest growing source of raw materials in polypropylene.

Due to China's abundant coal resources and relatively stable coal prices, the cost of preparing polypropylene from coal fluctuates slightly. Meanwhile, polypropylene is easy to process and form, with a simple production process, and its production cost is far lower than other existing plastic materials.

At present, many companies also use high-performance PP materials developed by our company to replace ABS materials for the refrigerator panel. The shell and base of electric rice cookers were previously made of ABS materials, but due to cost pressure, high-performance modified PP is now commonly used instead of ABS materials.

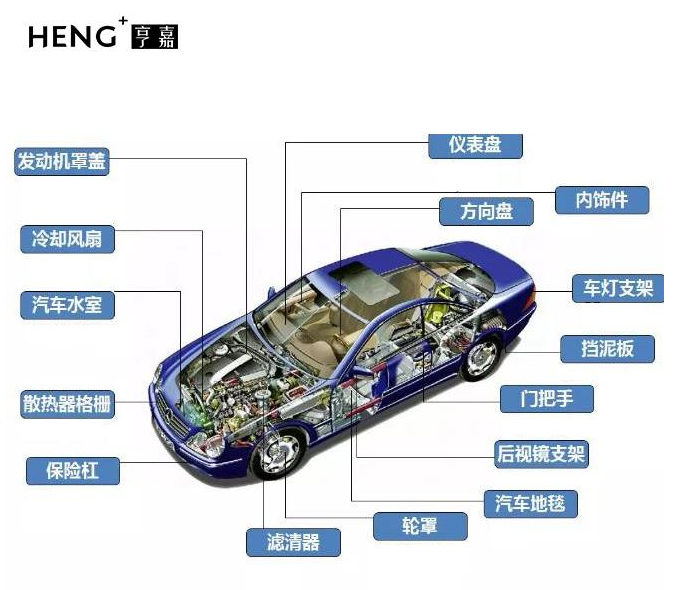

So, specifically, what are the applications?

Bumper

Fender

Instrument board

Fanblade

Other applications

Polypropylene and its modified polypropylene materials are not only used in car bumpers, mudguards, instrument panels, and fan blades, but also in front end modules, shifter seat bottoms, bottom guards, sunroof drainage channels, engine covers, gear box bases, rearview mirror brackets, door inner panels, seat guards, door guards, column guards, parcel shelf guards, rear guards, fuel tanks, radiator water chambers, accelerator pedals, etc Truck bumper brackets, etc.

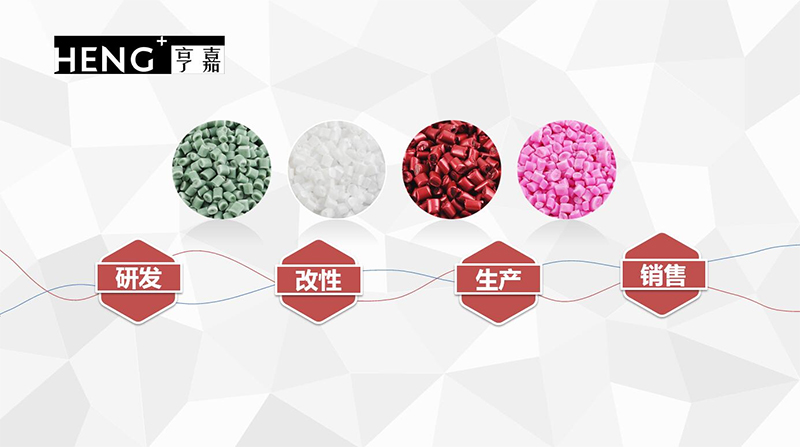

Guangdong Hengjia Rubber and Plastic Technology Co., Ltd. focuses on modified PP materials and is a comprehensive service-oriented enterprise that integrates technology research and development, modification, production, and sales, focusing on high-performance modified polypropylene. The company has two production bases: Jiujiang in Jiangxi and Changping in Dongguan, equipped with 16 production lines, independent research and testing centers, and color matching centers. It has an annual production capacity of 35000 tons of engineering plastic production equipment and is one of the high-end modified PP production bases in China.

Serving various industries such as automobiles, consumer electronics, home appliances, military industry, 5G, etc., we use innovative material technology to assist customers in creating new products. We help customers overcome various problems such as long lead times and slow reactions from foreign suppliers in the development of new products, high prices of existing imported products, and low technical content of existing domestic suppliers. We provide customers with solutions for modified polypropylene new materials.

Our company has been awarded the honorary title of 'National High tech Enterprise'. In January 2018, we were elected as the first council member unit of Dongguan High tech Industry Association, and for three consecutive years, we have served as the vice president unit of Guangdong Plastic Industry Association and Shenzhen Polymer Industry Association; Obtained ISO9001:2008 quality management system certification and ISO/TS16949:2009 quality management system certification.